Filtration Products

UFT products are available in the global market for various filtration applications. Our product has exceptional performance in clean air intake systems by improving filtration efficiency with low operating pressure drop to extend the lifetime and for cost reduction of filter maintenance.

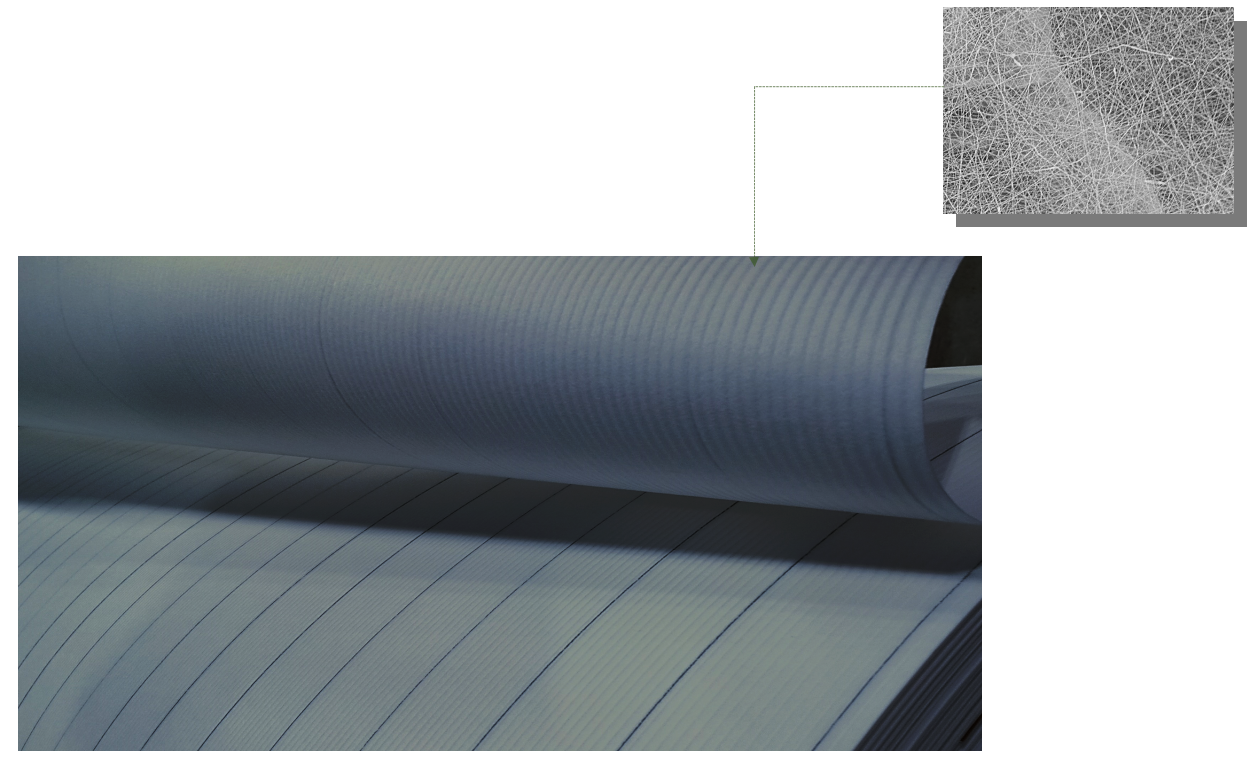

Gas Turbine

Advantages

- High performance

- Extended life time

- Excellent surface filtration

- Excellent water repellency

- Highest performance F7 – E10 Efficiency for pulsed application

- Highest performance F7- H12 Efficiency for static application

Application

- Thermal Power plants:

- Gas

- Coal

- Petroleum

- Diesel Generator

Air Pollution Control

Advantages

- Excellent emission control

- Excellent surface filtration of the particulates

- Low operating pressure drop over the life of the filter

- Excellent pulsability

- Increased productivity in dust collection

- Reduce operating cost

- Best class in the filtration

Application

- Chemical and Pharmaceutical

- Cement and Lime

- Food industries

- Mineral processing

- Metal refining and processing

HVAC Filter Media

Advantages

- Meets EN779-2012 and ISO 16890 standard

- Typically 40% lower pressure drop than glass fiber

- Energy savings to meet Eurovent A+ standard Robust and easy to crease with all pleaters

- Stiffer than glass fiber meaning less glue bead separation needed 100% Polyester

Application

- Industrial HVAC filter

- Large commercial HVAC

- Clean room: HEPA, ULPA grades

- Cabin air & Appliance

Engine Filter Media

Air intake and diesel, fuel filtration.

Advantages

- High-Quality performance

- Low environmental load

- High-Efficiency particle removal: min. size 0.1µm

- Longer life filter renewal

Application

- Heavy duty

- Passenger vehicle

- Cabin air filter, fuels, Lubricant, coolant, and others

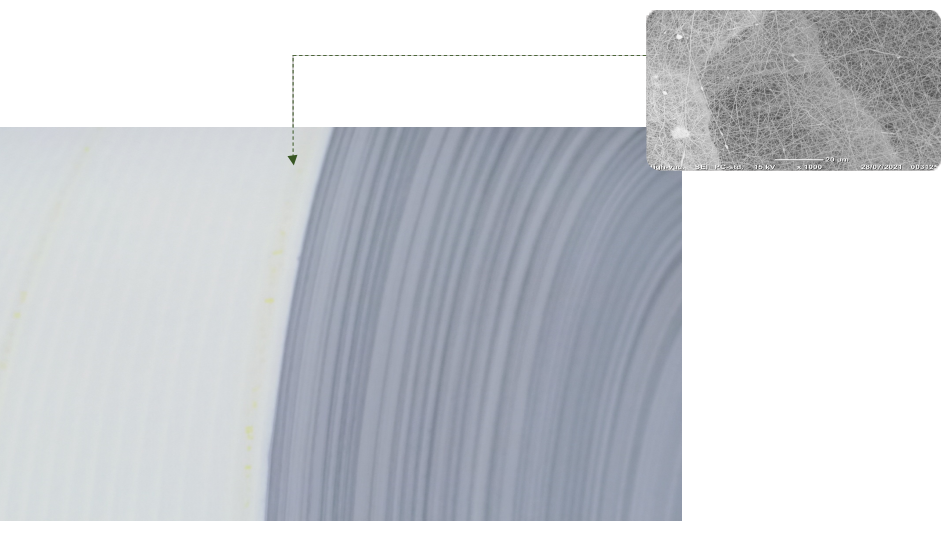

Liquid Filtration

Microfiltration

Ultrafine fiber was established for liquid filtration and is made from Nylon, PVDF and PU Polymers using a patented manufacturing process. Our membrane is explicitly designed for the microfiltration industry. Our products have superior filtration efficiency and membrane properties with low-pressure drop and high flux rate compared with traditional cast or extruded film found in the market and are available in a wide range of pore size membranes from 0.2 up to 3.0 micron. With the exceptionally tightly controlled and uniform pore structure, the highest level of filtration efficiency from the bacterial challenge can also be attained and adopted by most major microfiltration cartridge producers

Advantages

- Superior porosity

- Very narrow pore size distribution

- Liquid filtration advantages

- Available pore size ranging from 0.2 microns to 3 micron

- Unique physical and mechanical performance

- Suitable for operating & working conditions

Application

- Food & Beverage

- Purifier, drinking Water

- Automation Processing filter

- Wastewater treatment

- Micro-electronics

- Biopharmaceutical

- Sea Water Treatment (UF/MF)