With over 20 years experience in the filtration industry and the use of over 500 patents,

UFT CAN. INC. is a leader and trendsetter.

Why Choose UFTCAN?

Restriction on use of Electrostatic filter media EN779 | EN1822 (2012):

- These standards apply to all filter media.

- The use of electrostatic and glass fiber media is now banned, including combi technology (GF+MB or Cellulose + MB)

- Need for stable filter property & quality

(mechanical structure properties) - Need for environment-friendly media Air Filter

Restriction of – Glass Fibers due to its carcinogenic properties and environmental pollutant:

- Concerns on waste disposal are becoming serious problems for the world

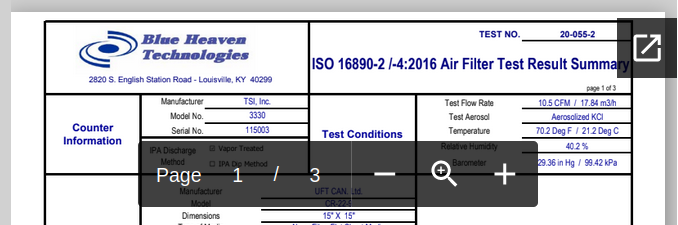

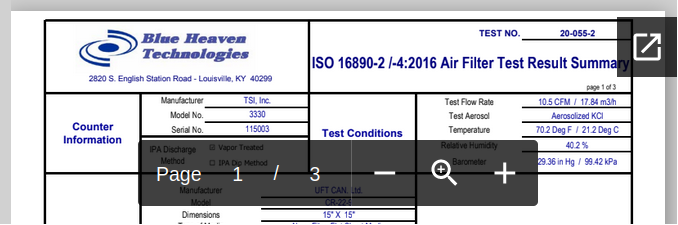

Meets the Standard EN779, EN1822:

- Compliance with strict standards for filter performance and quality

- New standards such as EN779, EN1822, ISO 16890 (No electrostatic charge)

- Environment-friendly materials Legal regulation against the use of Glassfiber for safety issues

- Higher efficiency with lower pressure drop

- Reduction in the cost of filter maintenance 2 1 3 4 Multi-functional features & Flexibility in value-added product

Growing demands on ultrafine fiber product:

- Meets the increasing demands for higher efficiency with lower pressure drop.

UFT Technology

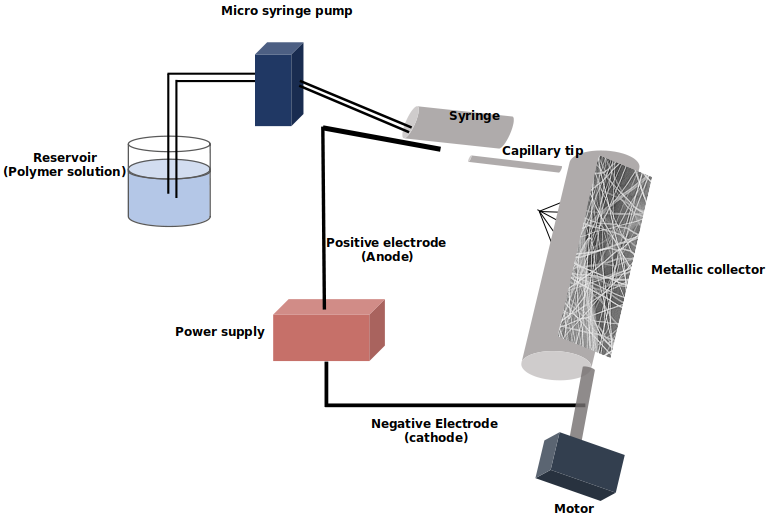

Electrospinning

Electrospinning technology is a versatile and effective method to generate continuous ultrathin fibers down to 1 nanometer in diameter. A nanometer is one billionth of a meter.

The polymer solution forms an equilibrium between gravity and surface tension at the end of the vertically located capillary. Accordingly, the hemispherical surface of the fluid at the tip of the capillary tube elongates to form a conical shape known as the Taylor cone. When the high voltage is applied to a form bubble liquid is called “droplets” on the tip, the body of the liquid becomes charged, and the electrostatic repulsion of the liquid droplets is stretched and divided into smaller jets and initialized to form of thin web fiber or a mat fiber.